Hunter touchless alignment system arrives in the UK

A brand-new revolutionary wheel alignment inspection system from leading equipment manufacturer Hunter, is now available and set to transform the fortunes of workshops all over the UK and Ireland.

The Hunter Quick Check Drive, available exclusively from wheel servicing specialist Pro-Align, is one of the industry’s first ‘drive-thru’ non-contact wheel alignment inspection systems. Without any need to attach sensors or targets, there’s not even any need for the vehicle to stop, meaning labour costs are minimised and alignment opportunities can be identified in a matter of seconds.

“The Quick Check Drive is a genuine industry game changer that could revolutionise the way workshops all over the country operate,” enthuses Greg Thompson, business development manager, Pro-Align. “With the system installed, there’s no reason why every vehicle entering a workshop can’t have a preliminary wheel alignment assessment carried out without any additional time or labour costs incurred. In doing so, workshops are likely to identify and convert so many work orders that they’ll wonder how they managed before Quick Check Drive!”

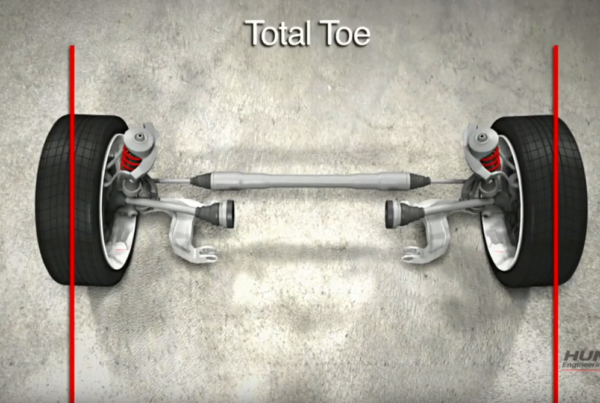

The Quick Check Drive system comprises of two slim profile units, which Pro-Align recommends are situated in the entrance to a workshop. Each of the units contains 16 lasers which are used to assess the vehicle’s total toe and individual camber measurements, and several cameras which are used to record 40-60 high-definition images of the car, helping to eradicate any fraudulent body damage claims.

In order to carry out the alignment assessment, the vehicle needs to be driven between the two measurement units at a speed of between 2-10 mph. Technicians or service advisors then simply need to input or confirm the vehicle make and model details, and the system cross-references Hunter’s extensive vehicle database to determine if the vehicle is within the manufacturer’s tolerances, or if a full 14-point alignment assessment is required. Such is the speed of the system that it can take new readings every 3-5 seconds.

Through its integration with HunterNet, alignment and bodywork image results can be viewed online, emailed to customers, or more likely, displayed on a live Flightboard in the service reception, providing an instant and totally transparent work opportunity for service advisors to discuss with customers.

“Quick Check Drive was launched in the United States late last year and the reception and results have already been incredibly impressive,” adds Thompson. “Some workshops, which were already busy alignment centres, have seen their alignment sales double since the introduction of the system. Not only does this benefit the customer by providing a more comprehensive and transparent service, but it clearly also offers workshops a fantastic return on their investment too.”

To find out more about the transforming potential of the Quick Check Drive, visit www.pro-align.info/qcd or call 01327 323007.